From Empty Lot to Move-In Ready: Your Practical Guide to Prefab and Modular Homes

Maybe you have a sketch on a napkin, or a tab open to a floor plan you keep revisiting. You want a real home, not years of budget creep and mud. This is where factory built housing changes everything. Consider this your practical guide to prefab and modular homes, a clear path from curiosity to keys in hand, minus the stress, guesswork, and the surprise bills that spook so many dreamers.

Why Many Builders Struggle and Buyers Pay

Traditional construction often asks you to fall in love with an idea, then hold your breath while weather, labor swings, and supply hiccups decide the outcome. Weeks slip by as framing sits under clouds, costs inch upward with every change order, and trades fight calendars instead of focusing on craft. No wonder people stall at the blueprint stage. Prefab and modular methods move most of the work indoors, into climate controlled facilities where materials stay dry, schedules are predictable, and measurements are laser accurate. Crews repeat proven steps on level surfaces, so fit and finish improve rather than drift. Waste is sorted instead of piled in a dumpster, neighbors deal with fewer early morning compressors, and inspections happen at multiple checkpoints before anything reaches your site. The surprising twist is that modular is not a synonym for bland. Panels and modules behave like building blocks, letting architects combine light, volume, and texture with more control. You still pour a foundation, you still choose cabinetry, tile, and fixtures, you just trade open ended risk for a defined process. That shift, from improvisation to orchestration, is what quietly lowers anxiety for first time buyers and seasoned homeowners alike.

A Step by Step Path You Can Actually Follow

Start with the site, because even the smartest module needs a place to land. A survey clarifies setbacks and utilities, then a soils report informs the foundation design. Next, browse a plan library to match your lifestyle, number of bedrooms, and the way sunlight moves across your lot. This is your practical guide to prefab and modular homes in action, a sequence that trades confusion for clarity. Factory engineering adapts the plan to your local code, structural loads, and climate zone, while a project manager lines up permits and delivery timing. Off site, crews frame, insulate, wire, and paint in parallel, so kitchen cabinets arrive already aligned and doors swing true. On site, the foundation cures while trenches carry power and water. When the crane day arrives, modules settle onto anchor bolts, seams are sealed, and final inspections close the loop. Want to go deeper before you commit, explore the buttons on this page to tap through plan filters, compare material packages, and run a quick cost and timeline calculator using your zip code. Checklists, glossaries, and a photo gallery of recent installs will help you see what matters most, from roof pitch to window performance.

What Changes When You Choose Factory Built

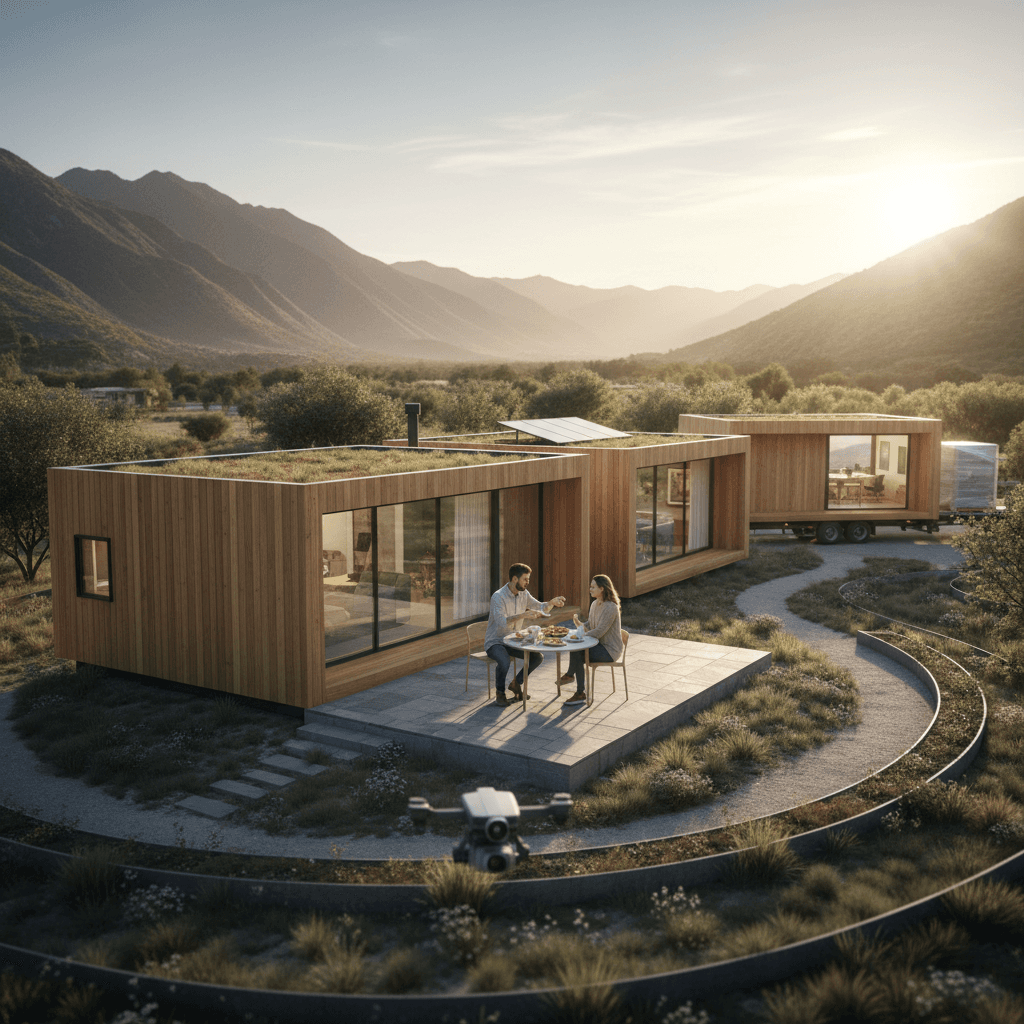

Picture a couple selecting a plan on a rainy Sunday, then sipping coffee six weeks later as a crane lifts the living room into the sunrise. They are not special, they just chose a method that compresses the messy middle. Predictable schedules mean moving trucks are booked with confidence. Fewer site deliveries reduce neighborhood clutter and noise, so you meet your new neighbors with cookies, not apologies. Indoor assembly helps keep insulation dry and continuous, which often translates to quieter rooms and steadier temperatures. Smart options, like high performance windows and airtight seams, pair with efficient HVAC to shrink monthly bills without shrinking comfort. Design is not an afterthought either. You can stretch a porch, add a mudroom, or flip the floor plan to frame a view, all while staying inside a controlled spec that keeps inspectors happy. Maintenance changes too. Factory applied finishes tend to be even, cabinets square up, and doors latch with that satisfying click that whispers longevity. If you are building a studio or an accessory dwelling for family, you get the same gains at a smaller scale, with less disruption to daily life. The upgrades shown on this page can reveal how far your budget can travel.

Open the Door to Your Next Chapter

Home is not just a purchase, it is a rhythm, a place where mornings start the way you want and evenings slow down on cue. Prefab and modular give you a way to reach that rhythm without sacrificing years of weekends to uncertainty. If this stirred ideas, linger here a little longer. Skim the project timelines, peek at the financing tips, and bookmark the plan gallery that speaks to you. You will find worksheets for comparing bids apples to apples, a glossary to decode builder jargon, and stories from homeowners who stood where you are standing now. Treat this page as your practical guide to prefab and modular homes, a companion you can return to as decisions stack up. When you are ready, send a quick inquiry, save a shortlist, or run a fresh estimate with different finishes to see how choices shape cost and schedule. Even small steps, like noting your must haves and nice to haves, will speed up conversations with pros. The door is already unlocked. All that is left is to turn the handle, take a breath, and picture the first morning sunlight landing on your own new floor.